This is a special Forum Thread made specifically for James Meeker to help with the "Care and Feeding" of his wide body beast of an M3 we called Chainsaw Massacre.

A track build this extensive needs some serious instructions, and while we made him a binder with wiring schematics, part numbers, and supplied individual instructions for various parts, this should forum post should work better for long term reference (this forum has been up for over 23 years).

After several track tests in the car, even when James stopped by to pick the M5 up after the 5th track test and last round of work on this car at Vorshlag, he made a list with 13 questions, which I will answer in chunks starting below.

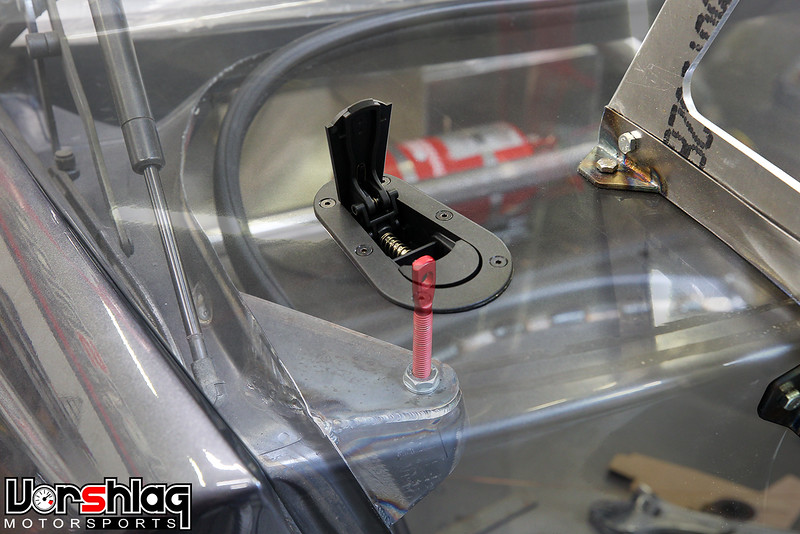

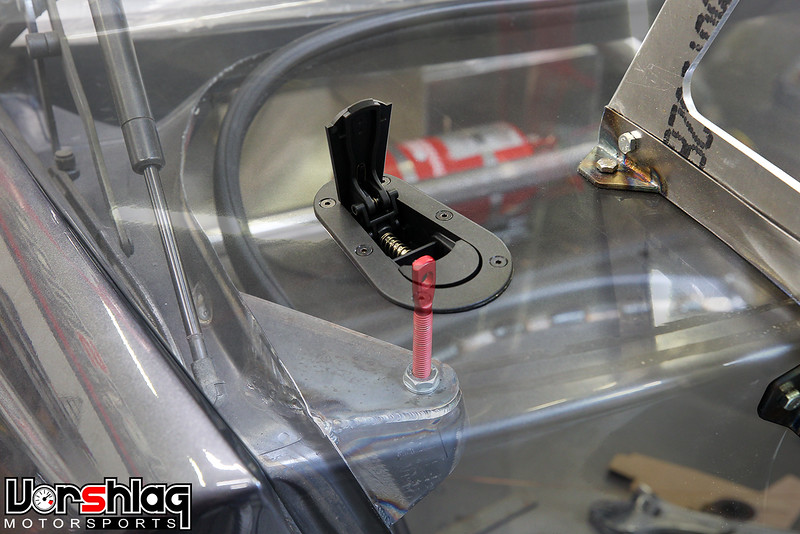

1. Hood Pins

Opening the hood and trunk is done with externally accessible AeroCatch lathes. This brand are still the best ways to secure hoods and and trunks without cable operated / OEM style releases - they can be accessed from the outside quickly without tools.

They have low drag and a very visible engagement when closed - as shown below, you can TELL when they are open, and if they are flat flush they are closed.

The only issue we ever see is that the retracting latch pin can sometimes get stuck in the bore and will not fully retract fromt he vertical chassis pin tower (the red bit which has a hole in it). It's easy to tell - the spring still looks compressed. If this happens, just shove on the latch at the spot shown below with your finger, it will go "pop" and the pin will retract.

A little spritz of WD40 on the pin will smooth out the action for a bit. There ya go!

2. Fire Bottle Pins (and how to use the Fire Suppression Systems)

Before each event, these two "safety pins" need to be removed from BOTH fire bottles. These pins have to be removed or the suppression systems cannot be triggered. After an event the pins should be replaced, so they are not accidentally discharged.

The fire suppression bottle that is behind the back seat (see above) is in the forward part of the trunk. It is easier to access the pin from the trunk side, however.

Brad built this special access panel to be able to remove / replace the pin. This panel should remain closed when driving, but it can be opened without tools.

There is a hinge at the bottom and a single "quarter turn" butterfly handle Dzus fastener at the top. Turn that butterfly, the panel can swing down, and the pin is visible.

The secondary fire suppression bottle is behind the passenger seat. You can just reach back from the front drivers seat and remove / replace the pin for that easily. The pins are pulled with what looks like a round key ring and can dangle from the plastic loop until they are reinstalled.

Remember, this car has a primary fire system for the engine bay and a secondary fire system for the passenger cabin and fuel cell. We figured it was well worth the extra $500 in fire system parts to run two, considering what was invested in this build. The "fire pulls" are the two red T-handles at the top of the center dash area (see below), with secondary pulls for both bottles located outside of the car at the A-pillar.

If you ever suspect fire immediately shut down the engine (hit the Cartek button - I will show that below) and get off the racing line (but don't go in the grass if it is dry - that can burn from contact with a hot exhaust). Once at a controlled stop GET OUT OF THE CAR. If you have time while slowing down, before the car has stopped PULL THE FIRE SYSTEMS. If in doubt, pull them both.

Car fires are luckily a VERY RARE thing to encounter, but still - nothing is more potentially dangerous while driving on track than fire. A car fire can happen in anything - even a normal street car. The general rule is: The more modified a car, the higher the risk. We regularly put a full fire suppression system in even a streetcar, nowadays.

Luckily James be driving the M3 with a proper fire suit, gloves, helmet and shoes + TWO fire suppression systems, so he is way ahead of the game. Yes, its worth the 40 pounds and other costs. In the five previous track outings every single driver and passenger has been properly outfitted in fire suits and gear.

Getting YOU and our passenger out is THE most important part. Release harness, yank the steering wheel off and set it aside, open the door and climb out FAST. You should practice this belted in with all of your gear on - the goal is 15 seconds or less. If you have to hit the external fire pulls and Cartek kill AFTER you have exited the car. Saving the equipment is secondary to saving YOU.

continued below...

A track build this extensive needs some serious instructions, and while we made him a binder with wiring schematics, part numbers, and supplied individual instructions for various parts, this should forum post should work better for long term reference (this forum has been up for over 23 years).

After several track tests in the car, even when James stopped by to pick the M5 up after the 5th track test and last round of work on this car at Vorshlag, he made a list with 13 questions, which I will answer in chunks starting below.

1. Hood Pins

Opening the hood and trunk is done with externally accessible AeroCatch lathes. This brand are still the best ways to secure hoods and and trunks without cable operated / OEM style releases - they can be accessed from the outside quickly without tools.

They have low drag and a very visible engagement when closed - as shown below, you can TELL when they are open, and if they are flat flush they are closed.

The only issue we ever see is that the retracting latch pin can sometimes get stuck in the bore and will not fully retract fromt he vertical chassis pin tower (the red bit which has a hole in it). It's easy to tell - the spring still looks compressed. If this happens, just shove on the latch at the spot shown below with your finger, it will go "pop" and the pin will retract.

A little spritz of WD40 on the pin will smooth out the action for a bit. There ya go!

2. Fire Bottle Pins (and how to use the Fire Suppression Systems)

Before each event, these two "safety pins" need to be removed from BOTH fire bottles. These pins have to be removed or the suppression systems cannot be triggered. After an event the pins should be replaced, so they are not accidentally discharged.

The fire suppression bottle that is behind the back seat (see above) is in the forward part of the trunk. It is easier to access the pin from the trunk side, however.

Brad built this special access panel to be able to remove / replace the pin. This panel should remain closed when driving, but it can be opened without tools.

There is a hinge at the bottom and a single "quarter turn" butterfly handle Dzus fastener at the top. Turn that butterfly, the panel can swing down, and the pin is visible.

The secondary fire suppression bottle is behind the passenger seat. You can just reach back from the front drivers seat and remove / replace the pin for that easily. The pins are pulled with what looks like a round key ring and can dangle from the plastic loop until they are reinstalled.

Remember, this car has a primary fire system for the engine bay and a secondary fire system for the passenger cabin and fuel cell. We figured it was well worth the extra $500 in fire system parts to run two, considering what was invested in this build. The "fire pulls" are the two red T-handles at the top of the center dash area (see below), with secondary pulls for both bottles located outside of the car at the A-pillar.

If you ever suspect fire immediately shut down the engine (hit the Cartek button - I will show that below) and get off the racing line (but don't go in the grass if it is dry - that can burn from contact with a hot exhaust). Once at a controlled stop GET OUT OF THE CAR. If you have time while slowing down, before the car has stopped PULL THE FIRE SYSTEMS. If in doubt, pull them both.

Car fires are luckily a VERY RARE thing to encounter, but still - nothing is more potentially dangerous while driving on track than fire. A car fire can happen in anything - even a normal street car. The general rule is: The more modified a car, the higher the risk. We regularly put a full fire suppression system in even a streetcar, nowadays.

Luckily James be driving the M3 with a proper fire suit, gloves, helmet and shoes + TWO fire suppression systems, so he is way ahead of the game. Yes, its worth the 40 pounds and other costs. In the five previous track outings every single driver and passenger has been properly outfitted in fire suits and gear.

Getting YOU and our passenger out is THE most important part. Release harness, yank the steering wheel off and set it aside, open the door and climb out FAST. You should practice this belted in with all of your gear on - the goal is 15 seconds or less. If you have to hit the external fire pulls and Cartek kill AFTER you have exited the car. Saving the equipment is secondary to saving YOU.

continued below...

Comment